How great is the effect of changing to lighter wheels? There are many advantages for lightweight forged wheels.

1. Reduce the weight of the whole car, save fuel, but also more environmentally friendly. According to Japanese experiments, the weight of the 5-seater car per 1 kg, a year or about 20L gasoline savings.

2. increase engine life: according to the engine load and efficiency curve, when the load is large to a certain extent, its efficiency is reduced, the marginal effect that each unit of increased load, the engine will be more strenuous, especially fuel consumption, engine load reduction, naturally reduce failure and extend life.

3. The acceleration performance and braking performance.4. Improve the handling of the vehicle, cornering performance.

Unstrung Weight is essentially a reduction in unstrung mass.

The effects are of course: improved acceleration and deceleration performance, cornering handling and stability, and comfort.

All-purpose! Is it universal? As the old saying goes, car tuning is a system project, and tuning is easy, but a balanced tuning is hard.

Lowering the under spring mass is one means, but don’t expect a qualitative leap just by changing a set of lightweight wheels, and then you can go out on the street and destroy the world in seconds. # What is the under spring mass about the spring mass under spring mass, we might as well put the structure of the car so to handicap a little

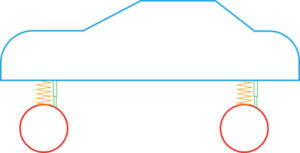

(Designer’s handicap series) The blue line is the body part, and the red line is the wheels and a series of other components.

drawing of car

Connecting the two is the yellow line of the spring and the green part of the shock absorber, of course there is a series of suspension mechanisms to restrain the range of wheel hopping on the real car, here handicapped omitted.

Structurally speaking, the under spring mass part includes the red, yellow and green parts of the above figure, namely (but not limited to): wheels, tires (including screws), swing arms, springs, shock absorbers, tie rods, brake assemblies (brake drums or brake discs + abalone), some models also have to count the driveshaft, integral axle and so on.

In fact, you can think of it this way, the reason why the above picture is drawn in this odd way, is to let people who have no concept of the spring on the spring will think of the car as such a thing: the car can be divided into two parts, part is rolling forward against the ground, this part of the spring and shock absorber removed can still be placed firmly on the ground, this part is under the spring.

The other part is the superstructure of sitting people, this part will collapse and kiss the ground if the suspension is removed, there must be springs and shock absorbers to support this part. And this part is the spring on. The two are connected by springs and shock absorbers.

(Of course, springs and shock absorbers are generally considered under spring). Understanding this is fundamental to figuring this out. This is where I’m not too happy with the explanations of under spring mass optimization I’ve seen in the automotive press so far, and it’s much clearer to build this simplified model and then think about under spring mass optimization. # There is an argument for lowering under spring mass: 1 kg under spring, 10 kg over spring.

This statement is, of course, anecdotal, but the actual situation is more complex and requires consideration from two perspectives: the benefits of under spring mass reduction alone, and the impact of combined upper and lower spring mass on the vehicle.

First, look at the impact of reduced under spring mass in isolation. This is mainly in terms of acceleration and deceleration performance. This is also referred to as 1 kg under the spring and 10 kg on the spring. The original wheels are high (shan’t) imitation (Thai) Losses casting 19, tossed into the Ended spin die-cast 18, with a set of forged aluminum screws.

Box measured 01 speed climbed from 5.9 seconds to 5.7 seconds. Then this guy ordered a set of AD08R, aiming for 5.5 seconds. Braking was not measured, there should also be some improvement. The principle is easy to understand. As a component directly connected to the half-shaft, the rotational inertia of the wheel and tire has a very direct impact on the performance.

No matter if it is 250PS or 280PS, 350Nm or 420Nm, the rotational inertia of the wheel tires must be overcome before the torque can be transferred to the ground through the wheel tires. Reducing the weight of the wheel tires (and of course the brake discs that rotate together) allows for a more direct transfer of power.

However, the impact of rotational inertia on acceleration and deceleration performance alone is nothing to do with the abalone and swing arm. Because they do not rotate with the wheel, the ability to drag the rear end is no different from the upper part of the spring. So those who change the abalone and discs also like to weigh the youngest are how to think?

This brings us to another aspect of consideration. # Spring to spring mass ratio this will have to use the above handicapped out of the simplified model. For the car, the road is definitely not smooth as a mirror. Not to mention the various potholes speed bumps manhole covers, a variety of stones will also cause jumping, not to mention a closer look at the tarmac, the surface is considered very rough. But in the comfort of the car, we feel is silky smooth. In addition to the use of softer spring shock absorber combination, increase the spring to spring mass ratio is also a proven means.

The truck has such an interesting characteristic: when empty, the car is upside down, must be loaded with something to drive up like that. Of course, I have never driven a truck, this is Jeremy Clarkson in Myanmar said. The reason for this is the increase in the spring-to-spring mass ratio.

Let’s go back to the simplified model. All the bounce on the road is first applied to the under spring portion, and the under spring portion needs to be re-influenced by the springs and shocks to the over spring. At rest, the weight borne by the spring is the weight of the upper part of the spring, and when the under spring encounters a bounce, the spring compresses or stretches, which breaks the balance and creates excess pressure. And according to Newton’s second law, the pressure exerted on the spring through the spring will also be exerted on the spring equally.

At this point, two paths are available (or both): first, increase the mass on the spring, as in the case of a truck load, by increasing the mass on the spring to weaken the acceleration caused by the under spring beating through the spring to the upper part of the spring.

The straightforward point is that the bounce is held down by the weight of the vehicle. Second, reducing the under spring mass allows the under spring to produce the same amount of bounce with less rebound to reduce the impact on the upper part of the spring. The combination of this is that the ratio of upper to lower spring mass needs to be increased.

Of course the ideal situation would be to reduce both the upper and lower spring masses, but to reduce the lower part of the spring more than the upper part of the spring, and the combined upper and lower spring mass ratio would still be increased.

Therefore, some people often say that the car is heavier and more stable at high speed, but it is more accurate to say that the mass ratio between the upper and lower springs is larger and more stable. # Can not ignore the spring and shock machine as a connection between the two blocks and responsible for the support, transfer of force, shock absorption part, the spring and shock machine selection has a greater impact. The spring and shock absorber are responsible for the support, force transmission and shock absorption. Still the same: modification is a system engineering, do not one-sided modification.

Naše lehká kovaná kola:

2 ks kovaných kol

kovaná výkonná kola