Heute wollen wir über die Arten von Autoreifen sprechen.

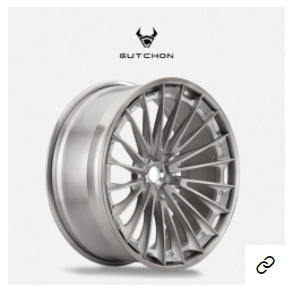

Today we are going to talk about wheels. On the one hand, nowadays, we have slowly upgraded from buying a car to having a car life, and the demand for modification and upgrading is not small

Wheels are mainly divided into two categories according to the manufacturing process.

1、Cast wheels

Casting wheels can be subdivided into three categories (gravity casting, low-pressure casting, spinning casting), and the differences in wheels under different casting technologies are large

Gravity casting manufacturing; the process is simple, that is, the liquid alloy is poured into the mold, cooling can be shaped, that is, by gravity to make it shape. Due to the durability of the mold and the simplicity of the process, it is the lowest cost manufacturing method, but the quality can also be imagined, the parts of the wheel may not be uniformly distributed, the molecular porosity inside the metal is large, the strength is also reduced a lot, the wheel is not uniformly stressed, easy to break and so on.

Low-pressure casting is to use low pressure to press the liquid alloy into the casting mold. A constant pressure is maintained all the time during the process, so that the molecules are distributed evenly with fewer pores, which ensures the density of the metal liquid at the same time, and also ensures the strength of the metal after solidification. The process of low-pressure casting is all done by machinery, and the high yield rate of casting molding is very suitable for mass production, and the cast aluminum alloy wheels specified by automobile manufacturers are currently produced by this process.

Spinning casting: It is mainly to process the rough wheel after casting, mainly to rotate and press the rim part, during which the rim part is heated and the rotating knife is rotated, and the rim is gradually stretched and thinned, and the metal molecules inside the rim are arranged more closely at this time. Therefore, the metal strength of the rim is higher, and the spinning casting wheel can be comparable to the forged wheel, although there will be some gap in weight, but the good thing is that there is a greater advantage in price!

2、Forged wheels

Forged wheels can be divided into: one piece forged wheels and multi-piece forged wheels

They are different in technology and structure.

One-piece wheel is a whole wheel, forging can be divided into two processes, forming forging (die forging) and milling forging, forming forging is forging, wheel shape has been basically shaped, milling forging is to buy ready-made forging wheel blanks, and then through the CNC machining center milling wheel shape.

Multi-piece forged wheels: can be divided into, two-piece and three-piece, and one-piece forged wheels, the most obvious difference is the difference in structure, two-piece wheels consist of two parts: the front piece, the rear piece, so three-piece wheels, by the front piece, the rear piece, the wheel width of three parts!

Let’s look at the differences between the two types of wheels.

1, casting wheels heavier weight, better toughness encounter more than the limit strength of the impact, will deformation and distortion, or even fracture, but normal driving is no problem at all, the price is also lower, the casting process of good wheels, and forged wheels comparable!

2, forged wheels are more exquisite technology, lighter weight, more rigid, less tough, but encounter more than the limit of the impact, will directly fracture, but the limit of the impact force, generally much higher than cast wheels, the price is also higher!

Summary: If you are a performance control then forged wheels are your choice, but if you are a common household driving, you do not need to pursue forging, because you forge casting usually you drive up will not make much difference.

In short, according to their own economic ability to choose on the good, if more money can not be used up, must choose expensive, then when I did not say.

So, to install a wheel to the car, what needs attention?

J-value

The width of the wheel (J-value) is the distance between the flange on both sides of the wheel. The “7.0” in wheel refers to 7 inches, and the “J” represents the shape and height of the wheel flange (there are also heights such as C, JJ, JK and K, with C being the lowest and K being the highest). The width of the wheel determines the width of the tire that can be mounted. Each J value has a recommended tire width, for example, for a 7J wheel, the standard tire width is 215, but of course a smaller 205 can be fitted, or a larger 225 width tire can be fitted, but neither is standard.

ET Value

ET is derived from the German word EinpressTiefe, which translates to “press-in depth”. The smaller the offset, the more the wheel will be out of the car after installation, which is often referred to by enthusiasts as “out of control”.

Hub Center Hole

This is better understood as the round hole in the center of the wheel. For example, the center hole of the Golf 7 wheel is 57.1mm, we should also refer to this value when choosing a new wheel: if the wheel is larger than this value, a reducer ring must be added to securely install the wheel on the bearing head of the car, otherwise the direction will be shaky.

Hole Pitch PCD

If the hole distance does not match the original data, you can only use torque, which will greatly affect the safety and stability of the vehicle. And if by chance the wheel you fancy is not the same as the original PCD, is there a remedy? This involves two sets of flange adapter and eccentric screws. But from the perspective of safety first, we do not recommend either.

We are professional in forged wheels for many years, if you are interested, you can visit our forged wheels here.

Monoblock-Schmiederäder

2 Stück geschmiedete Räder