주조 휠과 단조 휠의 차이점은 비용, 외관 및 성능에 있습니다. 방적 방식으로 주조 공정을 거친 휠을 주조 휠이라고 하고 단조 휠은 단조를 통해 만들어집니다. 이 둘의 차이점은 다음과 같습니다:

비용:

물레 기술은 비교적 간단하고 저렴한 비용으로 대량 생산에 적합합니다. 반면 단조 휠 기술은 복잡하기 때문에 비용은 높지만 성능은 뛰어납니다. 단조 생산 공정은 저압 주조에 비해 기계적 성능 지표가 크게 향상되고 특정 지표는 몇 배 더 높기 때문에 일반적으로 동일한 유형의 휠은 단조 휠이 저압 주조 휠보다 훨씬 더 비쌉니다.

모양:

두 가지의 외관을 구별하기는 어렵지만 금속 특성에는 상당한 차이가 있습니다. 단조 휠은 방적 휠에 비해 내피로성, 내충격성, 강도가 우수합니다. 일반적으로 주조 휠은 단조 휠보다 무게가 약 20% 더 나갑니다.

성능:

방적은 휠의 저압 주조 공정으로, 충전재가 압력 하에서 응고됩니다. 따라서 방적 휠은 충진성이 우수하고 다공성이 낮으며 밀도가 높습니다. 단조 휠은 일반적으로 휠 입자의 흐름 방향이 응력 방향과 일치하기 때문에 강도, 인성 및 피로 강도가 더 높습니다.

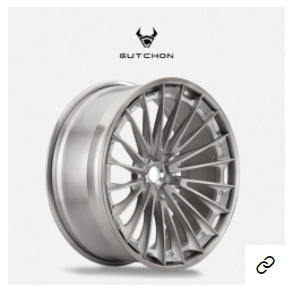

우리는 수년 동안 단조 휠을 전문으로하고 있으며 아래와 같이 더 많은 단조 휠을 찾을 수 있습니다.