The difference between powder coating and painting on wheel rims refers to the following:

Different principles: Painting involves adhering paint to the surface, while powder coating utilizes electrostatic attraction to adhere the powder to the surface.

Different forms: Painting is in liquid form, while powder coating is in powder form.

Different meanings: Painting is a type of synthetic paint made from nitrocellulose, resin, pigment, and solvent. Powder coating is a coating process that uses electrostatic discharge to attach powder coatings to the surface of the object.

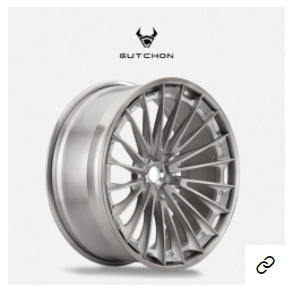

powder coating wheels

For the spray coating process of automotive wheel rims:

Pre-treatment: Remove oil and rust from the wheel rims, followed by washing and phosphating or passivating the rims. Then, dry and fix them.

Powder coating: Use an electrostatic spray gun to apply thermosetting powder coatings with an average particle size of micrometers onto the wheel drums. Place the coated wheel rims in a baking oven (either a box oven or a conveyor oven) for high-temperature curing, with a predetermined time and temperature setting.

After curing, inspect the color, metallic effect, adhesion of the coating, surface hardness, scratch resistance, and other aspects of the automotive wheel drums.

The purpose and advantages of automotive coating:

Coating automotive wheel rims through improved quality control of the coating process not only enhances their appearance but also protects them from environmental pollutants, thereby prolonging their service life.

Powder coating on automotive wheel rims serves to provide a smooth and corrosion-resistant covering. It effectively conceals any defects on the surface of the aluminum rims, facilitating subsequent processes.

Applying paint after powder coating enhances the appearance of the wheel rims, contributing to the overall aesthetics of the vehicle.

Jau daugelį metų profesionaliai gaminame kaltinius ratlankius, daugiau kaltinių ratlankių galite rasti žemiau.