A forged wheel is a wheel manufactured by forging and pressing, which removes the maximum amount of internal porosity and cracks.

It is often used in the form of multiple forging, which ensures the removal of material defects in all aspects and increases the internal stress of the material, making it more resilient and significantly improving the impact resistance and tear resistance at high speeds.

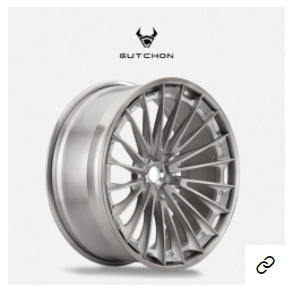

custom cnc wheels

Advantages and disadvantages of forged wheels

The advantages of forged wheels are high strength, higher safety, high plasticity, as well as lighter weight, good heat dissipation ability, fuel saving, etc.

At the same time, forged wheels are also the most advanced wheel manufacturing method.

The strength of these wheels is about 1 to 2 times greater than cast wheels, and 4 to 5 times greater than general iron wheels, so they are stronger and more resistant to collisions, and their toughness and fatigue strength are significantly stronger than cast wheels, and they are not easily crushed and fractured.

usa forged wheels

The only drawback is that they are expensive and have a long production cycle.

In addition, car enthusiasts do not blindly choose large rims when upgrading wheels, picking the shape of the wheel at the same time to take into account the weight of the wheel.

If you just want to look good and upgrade the large size of the wheels while increasing the corresponding weight, this will inevitably lead to an increase in fuel consumption of the whole car. It is also best to try to choose a relatively simple structure of the wheels, so that the wheels are easier and faster to clean, if the complex structure of the wheels may be refused by the car wash or increase the price.

We are professional in forged wheels modification for many years, you can choose our forged wheels if you are interested.