Modificação da roda do Mercedes-Benz E350

The hub, also known as the wheel rim (commonly referred to as “chebel”), is a term used in the automotive industry. The most common method of upgrading car hubs is by using aluminum alloy hubs or increasing the size of the hubs to improve the performance and appearance of the car.

Aluminum alloy hubs come in one-piece, two-piece, and three-piece designs. The two-piece design consists of an inner piece and an outer piece that are either welded or nailed together. The three-piece aluminum hubs utilize forged components, providing greater flexibility for small-scale manufacturing.

The performance of aluminum alloy hubs directly depends on the manufacturing techniques used. Low-pressure casting is the most basic and economical method. It involves pouring molten metal into molds and allowing it to solidify. Counter-pressure casting is a more advanced casting method where metal is forcefully sucked into the mold using a strong vacuum. This method helps maintain a constant temperature, remove impurities, and produce castings with uniform density and high strength. High counter-pressure mold casting (HCM) is a manufacturing process that achieves results close to forging. The RX/RY series aluminum hubs by the renowned German brand BBS, ranging in size from 381mm to 508mm, are manufactured using the HCM method. Forging is the most advanced technology for hub production, where a piece of aluminum ingot is pressed into a hub using pressure as high as 6000 tons while it is still hot. Hubs produced using this method have three times the strength of regular aluminum hubs and are 20% lighter. Roll forging (also known as die forging) is a form of forging that shapes the rough hub blank through rolling. Roll-forged hubs maintain sufficient strength while significantly reducing material thickness, representing the pinnacle of hub manufacturing. BBS’s RSH series utilizes roll forging.

Surface treatment processes for hubs can mostly be divided into two types: painting and electroplating. For ordinary vehicle models, appearance is given less consideration, and good heat dissipation is a basic requirement. The most common method used in the manufacturing process is painting, which involves spraying and then electro-coating the hubs. This method is relatively cost-effective and provides long-lasting, vibrant colors. Even if the vehicle is scrapped, the color of the hubs remains unchanged. Many Volkswagen models use the painting surface treatment technique. Some stylish and dynamic colored hubs also utilize painting technology. These types of hubs are moderately priced and available in various specifications.

Electroplated hubs can be divided into types such as silver electroplating, water electroplating, and pure electroplating. Although silver electroplated and water electroplated hubs have bright and vivid colors, their color retention time is relatively short, resulting in lower prices. Pure electroplated hubs have long-lasting color retention and are of higher quality and price. Mid to high-end sedans such as Guangzhou Automobile and Audi often choose pure electroplated hubs, which are more expensive.

Main parameters of modified hubs:

Rim Width: Typically expressed as 5.5J, 6J, 7J, measured in inches. For example, a tire width of 185 requires a rim width of 5 inches, 195 requires 6 inches, 205 requires 6.5 inches, and a tire width of 215 needs a corresponding 7-inch wide rim.

Rim Diameter: Available in sizes such as 12, 13, 14, 15 inches. Currently, there are models on the market equipped with 20-inch rims, such as Infiniti FX35 and BMW X5.

PCD Value: The diameter of the circle formed by the tire bolts, measured in millimeters. Domestic cars usually have values of 100, 114.3, while European cars have more specific values, including 98 for Acura series, 108 for Volvo, 120 for BMW, and 112 for Mercedes-Benz.

Center Bore: Ensures that the geometric center of the rim aligns with the geometric center of the hub, preventing steering wheel vibration when driving at high speeds.

Geometric Centerline: The most important reference data for the rim, including calculating the Offset value and the net distance between the leaf spring, all of which must be based on this value.

Offset: The distance between the fixed surface of the hub and the geometric centerline. Its most important role is to ensure that the tire does not rub against the vehicle body.

Rim Face: Supports the tire tread and absorbs impact from the road.

Rim Shoulder: Forms a tight seal with the tire bead, providing good airtightness to establish tire pressure.

Rim Disk: In some rims, claw-like features may protrude beyond the vertical line of the disk surface, leaving the rim vulnerable to damage if not careful when parking, potentially affecting the rim’s coating.

X-Distance: An important data point to consider when fitting multi-piston calipers. Otherwise, there may be friction between the rim disk and the brake caliper.

Many useful pieces of information are molded onto the sidewall of the tire, including tire type, tread pattern, specifications, whether it has an inner tube, speed rating, load index, aspect

The tire sidewall of a passenger car is as follows: Example: P215/65R15 89H

“P” refers to passenger car tires (distinguishing them from tires suitable for trucks or other vehicle types).

“215” indicates the tire’s section width, which is the width between the two sidewalls in millimeters. This width varies depending on the width of the rim the tire is matched with: wider rims require wider tires, while narrower rims require narrower tires. The specified tire width on the sidewall generally refers to the width when the tire is mounted on the recommended width of the rim.

“65” is the aspect ratio of the tire, which is the ratio of the tire’s height to its width. Here, it indicates that the height of the tire is 65% of its width. A smaller value represents a flatter tire.

“R” indicates the tire’s construction, indicating that it is a radial tire. It means that the tire’s ply layers are arranged in a radial pattern within the tire carcass. “B” would indicate a bias-ply tire, but such tires are no longer used for passenger cars.

“15” represents the rim diameter in inches. This tire must be matched with a 15-inch rim for proper installation.

“89” represents the load index, indicating the maximum load capacity of the tire. In this case, the tire can handle a maximum load of 1,279 pounds. Different load index values correspond to different maximum load capacities, typically measured in pounds or kilograms.

“H” represents the speed rating, indicating the maximum speed capability of the tire. In this case, the tire is rated for a maximum speed of 130 miles per hour. In the older European tire labeling system, it would be represented as 215/65HR15, where different letters represent different speed ratings.

“DOT” indicates that the tire complies with the safety standards set by the U.S. Department of Transportation (DOT). The following 11-digit alphanumeric characters after “DOT” represent the tire’s identification number or serial number.

Wheel Manufacturing Techniques The production of lightweight alloy wheels can be broadly categorized into two manufacturing methods: casting and forging. Casting aluminum wheels involves creating a sand mold, which represents the desired shape of the wheel. The aluminum material is then heated to its melting point, transforming it into a liquid state. The molten metal is poured into the sand mold and allowed to cool. Once the mold is opened, a formed aluminum alloy wheel can be observed.

On the other hand, forging aluminum wheels also requires the creation of a mold, but in this case, a sturdy steel mold is used instead of sand. During forging, the aluminum material does not reach a liquid state but is heated to a temperature where it becomes soft. The softened material is then placed into the steel mold, and significant force is applied to shape the aluminum into the predetermined form. The result is a forged aluminum alloy wheel.

When casting, air can be trapped inside the material as the molten metal is poured into the mold. As the metal gradually cools and solidifies, numerous small air pockets can form within the metal, resulting in a rough and irregular metal structure. In contrast, during forging, the metal is heated only to its saturation melting point (solid state), and high pressure is applied instantaneously to shape the material. This process eliminates the presence of air pockets within the material, resulting in a dense and well-organized metal structure. Consequently, forged wheels exhibit a more uniform overall strength and are relatively lighter in weight, making them better suited for use in wheel applications.

The continuous stamping process involved in forging ensures a highly compact and solid structure after forming. For instance, BBS lightweight wheels are manufactured by heating the billet material to around 450°C and subjecting it to instantaneous impact pressure of over 4 tons (4000 kg) per 1 cm using a hydraulic press. This enables the wheel to withstand higher stress levels. In comparison, cast aluminum wheels may deform when encountering road potholes. Additionally, due to the dense and high-stress capacity structure of forged wheels, they offer greater flexibility in design, allowing for more intricate spoke patterns without compromising strength. When comparing wheels of the same size, forged wheels can also be lighter than cast wheels. This improves the “load-bearing weight/non-load-bearing weight ratio” of the vehicle, enhancing handling performance without requiring further adjustments or modifications.

In addition to emphasizing the use of ACQ (Air Craft Quality) aerospace technology materials, another major advantage of BBS wheels is the utilization of the challenging cold extrusion manufacturing technique. Forged wheels are created by applying several thousand tons of pressure to shape an alloy into the desired wheel form, resulting in higher production costs compared to casting. Due to the high pressure involved, the gaps between the alloy molecules decrease, leading to greater interaction forces. As a result, the entire wheel requires less material to achieve sufficient rigidity, resulting in a lighter overall weight. The reduced rotational inertia of lightweight wheels significantly enhances the responsiveness of the car’s acceleration, braking, and cornering. It’s similar to the experience of switching from heavy shoes to lightweight running shoes, where the lighter wheels provide a more exhilarating acceleration experience. Hence, the saying that reducing the weight of a wheel by 1 kilogram is equivalent to reducing the weight of the vehicle body by 5 kilograms is not an exaggeration.

Enhanced Safety with Proper Upgrading When tires are modified to be wider and larger, the grip and friction increase, reducing lateral vehicle sway and improving braking and high-speed handling performance. This leads to significant improvements in vehicle acceleration and braking capabilities. While increasing the hub diameter and width can enhance the stability, heat dissipation during braking, and stability during cornering, it also corresponds to increased fuel consumption. Additionally, high-quality upgraded wheels are lighter than original factory wheels. Wheel mass is considered as part of the vehicle’s “unsprung mass,” and generally, reducing 1 kilogram of unsprung mass is equivalent to reducing the weight of the vehicle body by 4 kilograms. Therefore, high-quality wheels also contribute to the improvement of the vehicle’s power performance.

When increasing the wheel diameter, the sidewall height of the corresponding tires will decrease. The modified wheel diameter (tire sidewall height × 2 + wheel diameter) should be the same as the original wheel diameter; otherwise, there may be deviations in the speedometer readings, and interference between the wheels and the vehicle body during bouncing.

Blindly increasing the wheel size is also not advisable. The flatter the tire, the thinner it becomes, resulting in poorer shock absorption and sacrificing comfort. If the tire becomes too flat and thin for the sake of width, it can easily get damaged on roads with gravel. Generally, there is a formula for changing wheel sizes. For example, if the original wheel is 14 inches and you want to upgrade to 16 inches, the maximum diameter change should not exceed 2 centimeters. It is best to increase the wheel size by one or two inches based on the original wheel size and seek advice from professionals.

Moreover, the parameters of the wheel, such as bolt pattern and offset, should be compatible with the vehicle model. It is advisable to consult with professionals when making a purchase. This means that the selection process should not solely be based on personal preferences for appearance but also consider the advice of technicians regarding suitability. Additionally, wheels with complex and varied structures may appear more aesthetically pleasing and upscale but can pose difficulties during cleaning and maintenance and may affect brake cooling. Therefore, simpler wheel designs can be more dynamic, clean, and easy to maintain.

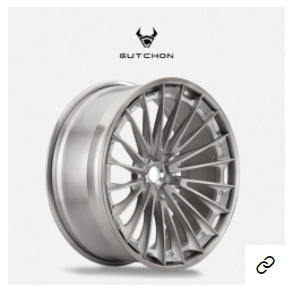

We are professional in forged wheels for many years, you can find more forged wheels like below.