Introducerea butucilor de roți auto 2

Who says there’s no difference in wheels! Lesser-known facts about wheels that you don’t know!

Wheels come in various styles, and car wheels are often susceptible to scratches from stones or damage from harmful substances like insects, leading to rusting. Many car owners have started paying more attention to wheel protection. With the rapid development of the automotive industry worldwide, car wheels, as a critical component, have garnered increasing attention in terms of manufacturing processes and technologies. Traditional steel wheels have gradually been replaced by aluminum alloy wheels. Compared to steel wheels, aluminum wheels are one-third lighter and offer improved appearance and corrosion resistance.

A wheel consists of multiple parameters, and each parameter can affect the vehicle’s performance. Therefore, it is essential to confirm these parameters before replacing tires. In general, larger wheel sizes and higher tire aspect ratios on sedans create a visually appealing tension effect and improve vehicle stability. However, this may result in increased fuel consumption as a trade-off. Therefore, careful consideration is necessary before modification.

Types of Wheels:

Based on different vehicle characteristics and requirements, wheel surface treatments can vary, mainly divided into two types: paint baking and electroplating.

For regular vehicle models, the appearance of the wheels is not particularly prominent, and good heat dissipation is a basic requirement. The paint baking process is commonly used, involving spraying and baking, as it is cost-effective, offers attractive colors, and maintains their appearance for a long time. Many Volkswagen models utilize the paint baking process for wheel surface treatment. Some trendy and dynamic colorful wheels also employ paint baking technology. These wheels are moderately priced and available in various specifications.

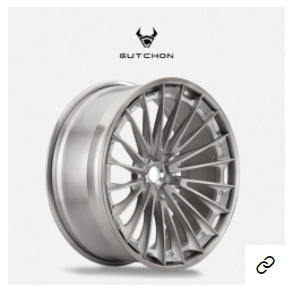

Electroplated wheels can be further categorized into electroplated silver, electroplated water, and pure electroplating. Although electroplated silver and electroplated water wheels have vibrant colors, they have a relatively short lifespan, making them cheaper and appealing to many young people who seek novelty. Pure electroplated wheels have a long-lasting color and can be considered high-quality products.

However, compared to steel wheels, alloy wheels are significantly more expensive. Therefore, in many mid- to low-end factory-fitted cars, steel wheels are found in the base models, while alloy wheels are standard in higher-end models.

PCD: It stands for “Pitch Center Diameter” and represents the diameter of the circle that passes through the center of several mounting screw holes. It is an important assembly parameter.

ET: It stands for “OFFSET” and represents the distance between the mounting face of the wheel and the centerline. It is an important assembly parameter.

modifying forged wheels

When installing tires, it is essential to ensure even weight distribution:

Currently, alloy wheels are widely used in various vehicle models, and they offer the following advantages:

- Energy-saving: Alloy wheels are lightweight, manufactured with high precision, and exhibit minimal deformation during high-speed rotation. They have low inertia resistance, which improves the straight-line driving performance of the vehicle and reduces tire rolling resistance, thereby reducing fuel consumption.

- Safety: Aluminum alloy has a thermal conductivity three times higher than that of steel, resulting in excellent heat dissipation. This enhances braking performance, prolongs the lifespan of tires and brake discs, and effectively ensures safe driving.

- Comfort: Vehicles equipped with alloy wheels generally use low-profile tires with better cushioning and shock absorption performance. This significantly improves driving comfort on uneven roads or at high speeds.

Suntem profesioniști în roți forjate de mulți ani, puteți găsi mai multe roți forjate ca mai jos.